13 December 2023

Written by Brad Wentzel: Doctor of Business Administration (DBA) Alumnus

Frey’s Food CFO Brad Wentzel shares the similarities between disassembling a motorcycle and deconstructing a business strategy.

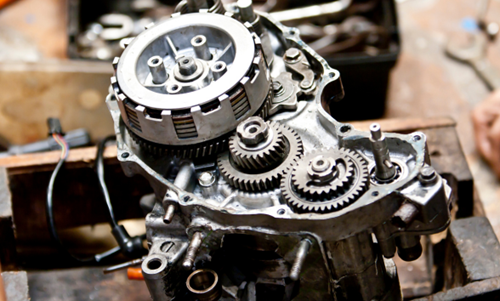

In the first part of this series, we looked at what you need to start building a motorcycle. Now, service manual in head and hand, it’s time to disassemble. My recent career change coincided with this phase of the motorcycle build, and the lessons, I’ve found, are very similar.

Deconstruction doesn’t mean to demolish, but instead means to dissect or fractionate something to discover its purpose, operations and significance. This process is a journey and it’s important to understand what those before us have put in place and incorporate their processes and responses.

As I’ve said time and again, this means leaders need to immerse themselves in every situation and get their hands dirty.

Getting dirty

I have witnessed many C-suite executives and their incumbents elevating themselves to a 30,000-foot view immediately upon arrival in a new business, which has always flummoxed me. Our world and the problems we need to address are so opaque from that height that you won’t be able to understand what is happening at the coal face.

This doesn’t mean leaders shouldn’t extract themselves from the details when it comes to developing strategic plans, as this is truly the raison d’être of their roles, but instead, they need to first immerse themselves in the business.

When it comes to building a motorcycle, the internal combustion engine has some ethereal inner workings, so attention to detail in the disassembly process will only help to understand what is really going on.

When you start a new build/project, inspect what you have received and ascertain the condition it has been handed over to you in. A glutton for punishment and someone who enjoys overcoming insurmountable challenges, most of the motorcycles I procure come in a sorry state – often mostly disassembled and divided into plastic containers or fridge drawers (as is the case currently). I then embark on the process of repairing and reusing parts that might have been discarded by others.

Taking it back to business, a big part of this journey is finding the shortcuts that have been incorporated into the business systems and restoring them to their true operational intentions, with the correct equipment and specifications.

This means taking your time to understand the workings of the business engine and the people that drive it.

Picking at the details

We have the privilege to live in such an incredible time, where technology and human knowledge have converged into a myriad of opportunities. These advances, often achieved through combinations of strategic planning, trial and error, and sometimes just fortuitously, have impacted every facet of our lives.

Below are the steps I’ve tried and tested when it comes to disassembling a motorcycle and business.

There is no one-size-fits-all approach, and on-the-job training, coupled with your service manual, is the best way to learn.